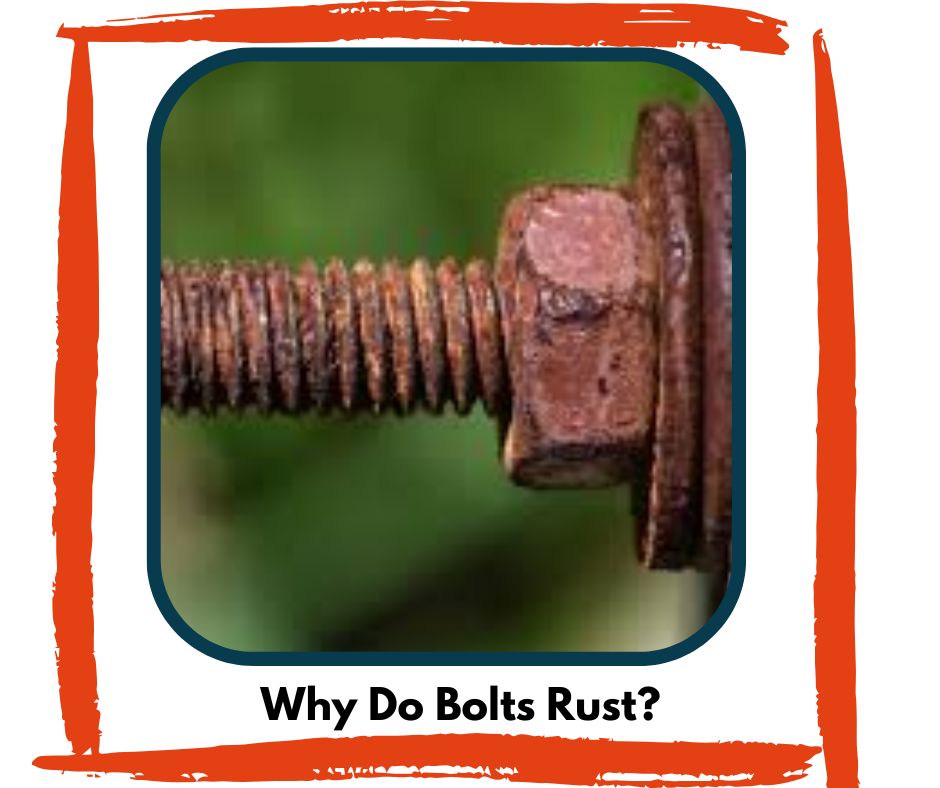

Why Do Bolts Rust?

Why Do Bolts Rust?

Bolts rust when they’re exposed to moisture and oxygen, leading to a chemical reaction called corrosion. This process breaks down the metal, causing it to weaken and look unsightly.

Most bolts are made of iron or carbon steel, both of which are prone to rusting when left unprotected. Rust can be a major headache, especially if you’ve poured time and effort into a project only to find the bolts corroding over time.

But the good news is, not all bolts rust—some materials are much better at resisting corrosion.

What Happens to Bolts When They Rust and the Problems That Can Occur

When bolts rust, it’s not just about the orange-brown flakes that make them look ugly. Rust can seriously weaken bolts, compromising the strength and stability of whatever they’re holding together. This can lead to:

- Structural Failure: If a bolt rusts badly enough, it can break under pressure. In extreme cases, this can cause parts of your project to collapse.

- Hard to Remove: Rusty bolts can become stuck and difficult to unscrew. If you’ve ever tried to remove a rusty bolt, you know how frustrating and time-consuming it can be.

- Aesthetic Damage: Rust stains can spread to nearby surfaces, ruining the look of your project, especially for things like outdoor furniture or decorative fixtures.

If your bolts start to rust, you might have to replace them entirely, costing more money and time. That’s why choosing bolts that don’t rust in the first place is key.

What Materials Are Best to Avoid Rusting?

To keep your projects safe from rust, it’s essential to use bolts made from materials that naturally resist corrosion. Here are some of the best options:

Stainless Steel Bolts

Stainless steel bolts are a top choice because they contain at least 10.5% chromium. This creates a protective layer on the surface, preventing rust from forming. Stainless steel is ideal for both indoor and outdoor use, as it holds up well in all kinds of weather. A2 is standard grade. For particularly harsh conditions, like coastal areas, A4 (or marine-grade) stainless steel is the best option.

Galvanised Bolts

Galvanised bolts are steel bolts that have been coated in a layer of zinc through a process called hot-dip galvanisation. This zinc layer protects the steel underneath from rusting, making galvanised bolts perfect for outdoor projects like fences, decks, and roofing.

Brass Bolts

Brass bolts are an alloy of copper and zinc, which makes them naturally resistant to corrosion. They’re great for environments with water exposure, but they’re softer than steel, so they’re better for decorative or low-load applications rather than structural tasks.

Silicon Bronze Bolts

Silicon bronze bolts are often used in marine settings because they resist corrosion in water, even in saltwater environments. They’re more expensive than other options but are perfect for demanding conditions.

Aluminium Bolts

Aluminium bolts are lightweight and naturally form a protective oxide layer that resists rust. They’re ideal for projects where weight is a concern and are often used in industries like aerospace and electronics.

Zinc and ZYP Bolts

Zinc-plated bolts, including those with a yellow passivate finish (ZYP), offer good corrosion resistance. They’re commonly used for indoor and outdoor applications where appearance matters, as they provide a smooth, polished finish while keeping rust at bay.

Titanium Bolts

Titanium bolts are incredibly strong and highly resistant to rust, but they come with a hefty price tag. If you need something for extreme environments and are willing to pay more, titanium is an excellent option.

Where Can I Get Bolts That Don’t Rust?

At Fix and Fast we’ve got you covered with a wide range of corrosion-resistant bolts for any project.

Whether you need stainless steel, galvanised, brass, or even titanium bolts, we provide high-quality fasteners that can withstand the elements. We help ensure your projects last without the headache of rust.

If you’re not sure what bolts are right for your project, we’re here to help. Our expert team can guide you to the best choice based on where your bolts will be used and what kind of load they’ll need to bear. No more worrying about rust—we've got the fasteners that’ll keep your projects strong for years to come.

FAQs About Bolts

Q: Why do my bolts rust even though I bought 'rust-resistant' ones?

A: Even rust-resistant bolts can corrode if they’re exposed to harsh conditions for long periods. Always match the bolt material to the environment. For example, regular stainless steel bolts may not hold up in salty coastal areas, but marine-grade stainless steel (A4) will.

Q: Can I prevent rust on bolts without replacing them?

A: Yes, you can try protective coatings like galvanising or use anti-corrosion sprays. However, these are temporary solutions, and you’ll likely need to replace the bolts eventually.

Q: What’s the difference between stainless steel and galvanised bolts?

A: Stainless steel bolts are rust-resistant because of the chromium in the alloy, which forms a protective layer. Galvanised bolts are steel bolts with a zinc coating that acts as a barrier to rust. Both work well, but stainless steel tends to last longer in more extreme environments.

Q: Can Fix and Fast help me choose the right bolts for my project?

A: Absolutely! We have a team of experts who can help you pick the best bolts for your project. Whether you’re building a fence or working on a marine project, we can guide you to the most corrosion-resistant options.

Q: Where can I buy corrosion-resistant bolts from Fix and Fast?

A: You can browse our wide selection of bolts on our website. We offer fasteners made from stainless steel, self colour, brass, and other materials to meet all your needs. Come direct to us on 01482 324731 and access an even bigger range of specialised corrosion-resistant bolts.

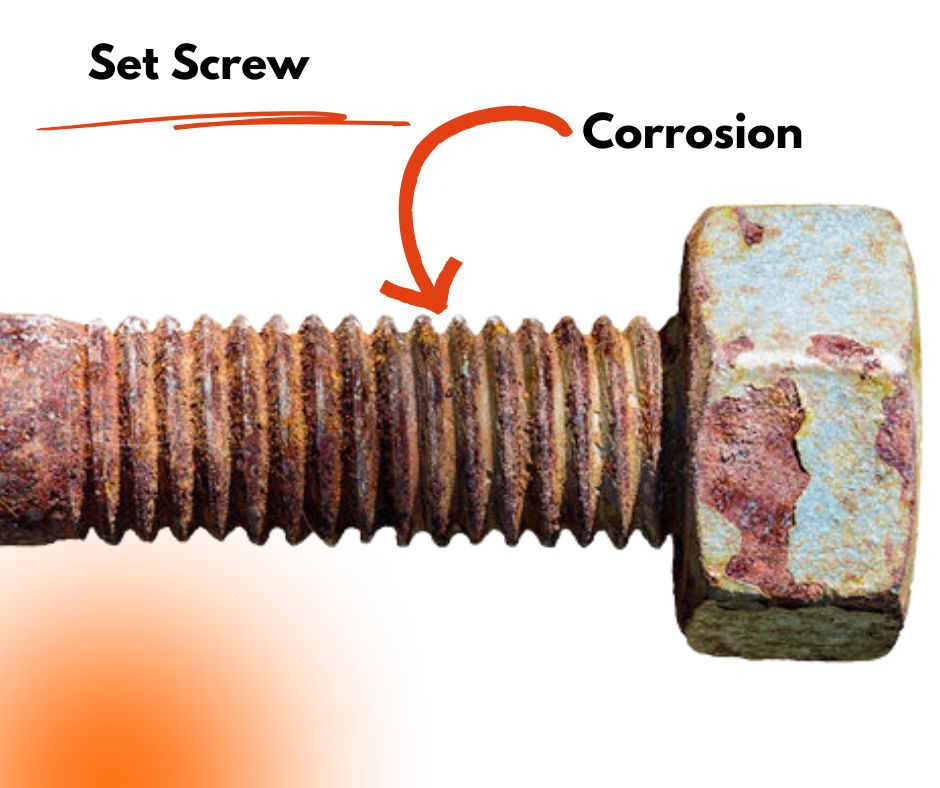

Q: What's the difference between a Set Screw and a Bolt?

A: A Bolt has a shoulder (or shank) whereas a set Screw is fully threaded is the main difference. Find out more about the differences from our friends at FR Scott here.

At Fix and Fast, we’re here to ensure your bolts stand the test of time—no rust, no worries!