How to Prevent Loose Screws & Bolts

How to Prevent Loose Screws and Bolts

Loose screws and bolts are more than a minor inconvenience—they can lead to equipment failure, leaks, and even safety hazards. But why do they loosen, and how can you stop it?

The fixings experts at Fix and Fast break it all down and offer practical tips to keep your fasteners secure.

Why do Screws and Bolts Come Loose

Understanding the causes of loose fasteners helps prevent the issue before it begins. Common reasons include:

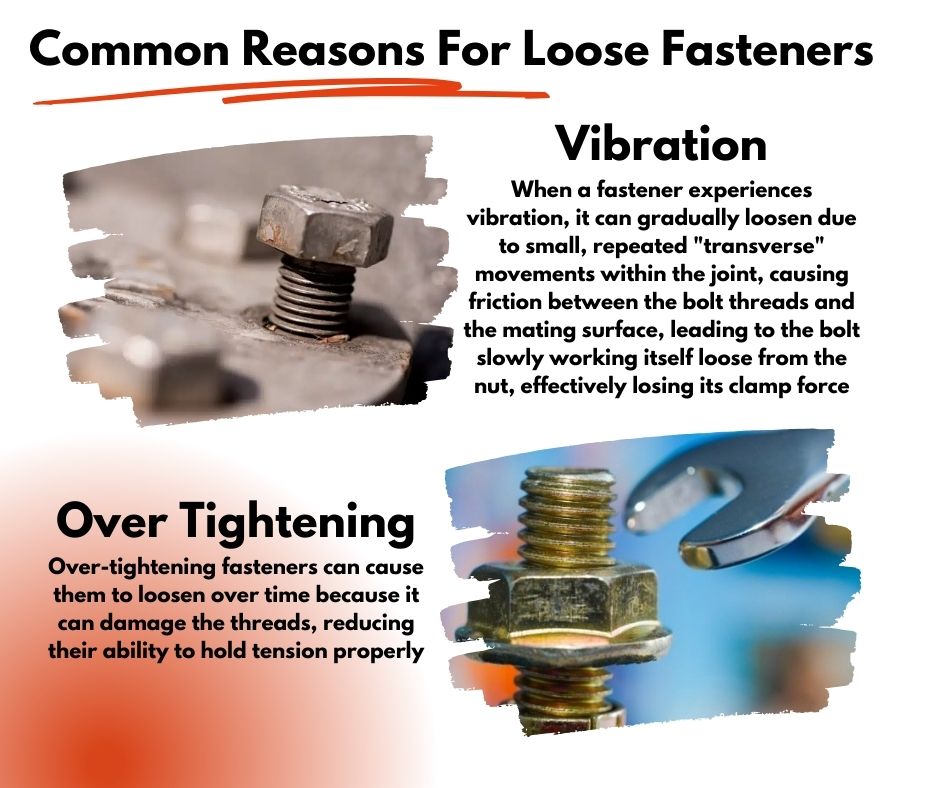

Vibration

Constant vibrations, such as those in machinery or vehicles, cause bolts to shift and “unwind.” Over time, this leads to loosening.

Thermal Expansion

Metal expands and contracts with temperature changes. This process, known as thermal cycling, can weaken the bolt’s grip.

Improper Tightening

Both over-tightening and under-tightening fasteners cause problems.

Over-tightening damages threads, while under-tightening leaves insufficient clamping force.

Damaged Components

Fasteners with worn threads or damage from improper installation are less effective at holding tension.

Shock Loads

Sudden impacts or dynamic loads create stress that can loosen bolts over time.

Embedding and Creep

Materials beneath fasteners can compress or “creep” over time, reducing tension. This often happens with gaskets or softer materials.

Tips to Prevent Loose Screws and Bolts

The key to preventing loose fasteners lies in proper design, installation, and choosing the right methods for your application. Here’s how:

- Use Locking Nuts

Locking nuts, such as nylon-insert nuts or all-metal locking nuts, are designed to resist vibration.

For higher performance, consider Aerotight nuts, which provide excellent resistance to loosening once installed.

- Install Wedge-Locking Washers

Wedge-Lock washers, like Nord-Lock washers, prevent bolts from loosening under extreme vibration.

These washers use interlocking cams to create tension, ensuring the bolt stays secure even in demanding applications.

- Apply Thread Lockers

Thread locker glue, such as a liquid adhesive, creates extra friction on the bolt’s threads.

Clean the threads thoroughly before application to maximize effectiveness. Using a thread locker is ideal for DIY projects and heavy-duty assemblies.

- Use Serrated Fasteners

Serrated screws or bolts feature grooves under the head that grip the material, reducing the risk of loosening.

These are ideal when washers are unsuitable for your assembly.

- Tighten Properly

Always tighten fasteners to the specified torque.

Over-tightening damages threads, while under-tightening reduces clamping force. Use torque tools to achieve precision and avoid “eyeballing” it.

- Incorporate Mechanical Locking Methods

Mechanical solutions, like cotter pins or tab washers, physically block the bolt from turning.

These methods are common in high-vibration environments, such as automotive suspensions and motorsports.

Choose the Right Fasteners for the Job

Selecting the correct screw or bolt for your application is critical.

For example, longer screws offer better grip, while screws with larger diameters reduce wobble.

Use washers to distribute load and reduce vibrations, especially with heavier or vibrating machinery.

Loose Screws - Final Thoughts

Loose screws and bolts are preventable with the right tools and techniques.

By addressing common causes like vibration, thermal cycling, and improper tightening, you can keep your assemblies secure and long-lasting.

At Fix and Fast, we provide a wide range of high-quality fasteners, washers, and locking solutions to suit every application.

Whether you’re assembling furniture or maintaining industrial equipment, we’ve got the fixings to keep things tight.

For help and advice get in touch with us sales@fixandfast.co.uk or call us on 01482 324731