How to Correctly use Washers with Screws and Bolts

How to Correctly Use Washers with Screws and Bolts

Washers are often overlooked in fastening systems, yet their role is essential in ensuring secure, durable, and long-lasting connections.

Whether you’re assembling furniture, repairing machinery, or working on a DIY home improvement project, understanding the types and correct usage of washers can significantly enhance the quality and longevity of your installations.

This guide explores the fundamentals of washers, their purposes, and how to correctly use washers with screws and bolts.

What Is a Washer and Why Is It Important?

A washer is a thin, disc-shaped component with a central hole that fits over a bolt or screw.

Despite its small size, a washer plays a pivotal role in distributing the load of a threaded fastener, reducing surface damage, and ensuring a tighter, more secure connection.

Washers are typically made of metal or plastic, with each material offering distinct advantages depending on the application.

Using washers helps protect soft materials like wood or aluminium from stress-related damage. Additionally, they reduce friction during tightening, prevent loosening due to vibration, and provide a protective barrier against corrosion and wear.

This makes washers indispensable for various applications, from household repairs to industrial machinery.

Types of Washers and Their Applications

Selecting the right washer is crucial for achieving the desired functionality. Here are the main types of washers and their common uses:

-

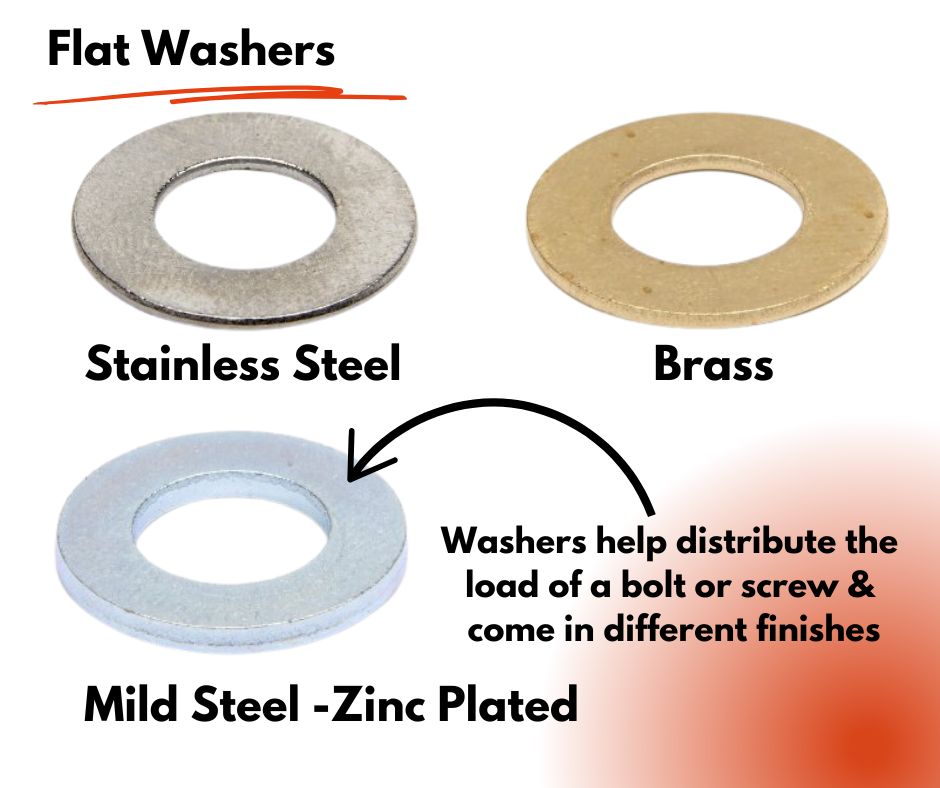

Flat Washers

Flat washers, also known as plain washers, are versatile and widely used.

Their primary function is to distribute the load evenly, preventing surface deformation or sinking under pressure. Flat washers are ideal for general manufacturing, maintenance, and repair tasks.

- Material Options: Metal for strength and durability; plastic for electrical insulation.

- Applications: Fastening furniture, securing appliances, and acting as spacers in assemblies.

-

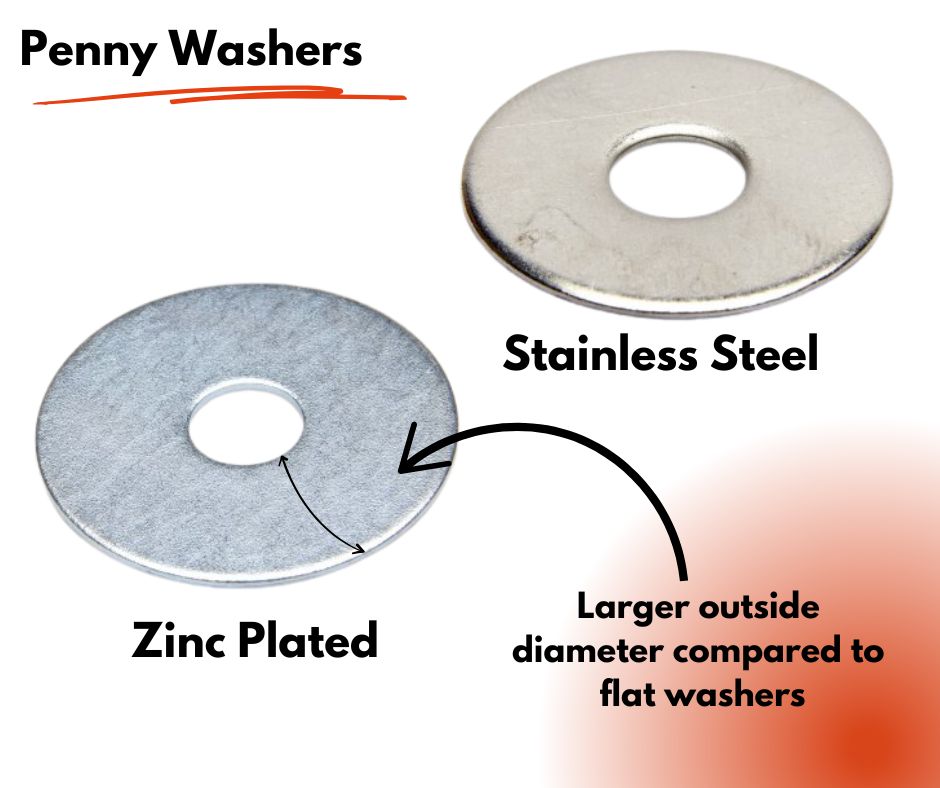

Penny Washers

Penny Washers – also known as mudguard washers - are a washer with a smaller hole and larger outside diameter.

Penny washers spread the load of a bolt or screw over a much larger area than a flat washer. They help prevent damage to the surface being fastened and used to secure large surface areas.

- Applications: Automotive – to secure mudguards and prevent the bolt heads being pulled through the rubber, Plumbing, Electrical engineering and Sheet Metal

-

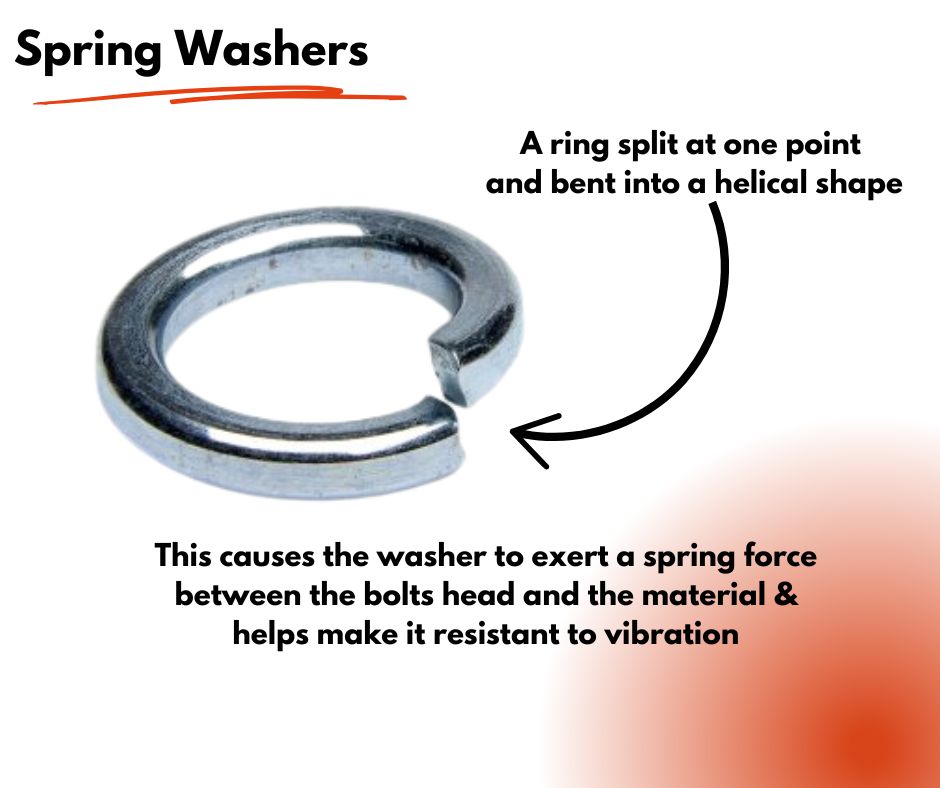

Spring Washers

Spring washers are designed to provide axial load and resist loosening caused by vibration or thermal expansion.

They are commonly used in high-vibration environments.

- Applications: Automotive components, aerospace systems, and machinery with moving parts.

- Varieties: Belleville washers (spring-like tension), wave washers (flexibility), and finger washers (specific load distribution).

-

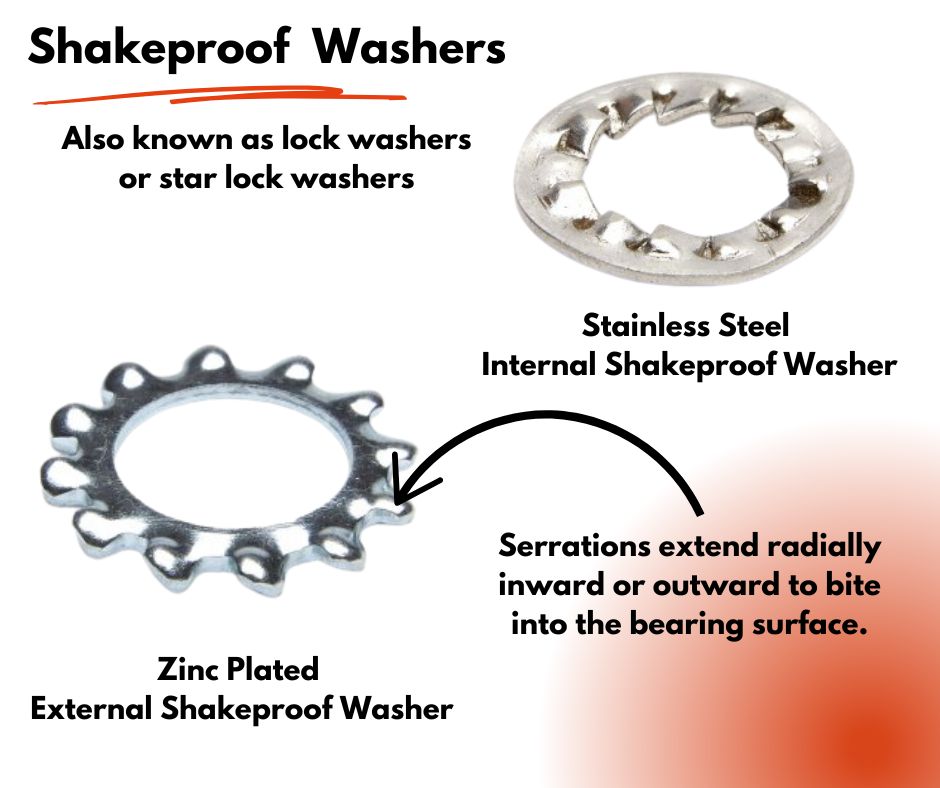

Shakeproof Washers

Shakeproof washers – also known as Lock washers or Star Lock Washers - are engineered to prevent threaded fasteners from loosening in high-vibration conditions.

Shakeproof washers have pointed teeth that bite into the surface being fastened. The teeth create friction and tension to keep the fastener in place

- Applications: Heavy machinery, automotive assemblies, and electrical equipment.

When and How to Use Washers

Proper use of washers can greatly enhance the safety and longevity of your installations. Here’s how to make the most of them:

When to Use Washers

- Prevent Surface Damage: Use washers to avoid dents or cracks in softer materials like wood or aluminium.

- Enhance Tightness: Washers can bridge gaps and distribute the load, allowing for tighter connections.

- Ensure Waterproofing: Thin washers can act as seals, preventing leaks in plumbing or outdoor fixtures.

How to Use Washers Effectively

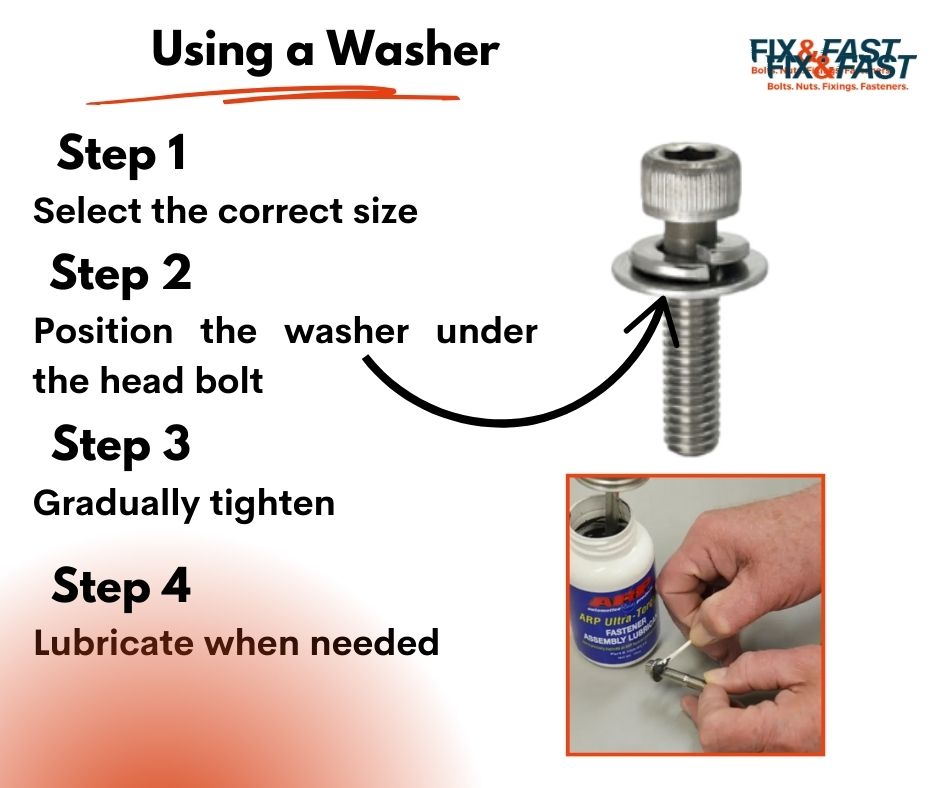

- Select the Right Washer: Match the washer’s size to the fastener and ensure it fits snugly. For added tightness, thicker washers can be used, while thinner washers work better for sealing applications.

- Positioning: Place flat washers under the bolt head or nut to distribute pressure evenly. Spring washers should be placed on the nut side for optimal load resistance.

- Apply Gradual Tightening: Use a torque wrench to evenly tighten screws or bolts, avoiding over-tightening that could deform the washer or damage the material.

- Lubricate When Needed: Applying grease to washers can make installation easier and help prevent rust.

Tips for DIY Using Washers

- Furniture Assembly: Use flat washers to prevent screws from sinking into wooden surfaces, ensuring stability and longevity.

- Plumbing Projects: Opt for washers with waterproofing properties to seal pipe connections and prevent leaks.

- Vibration-Prone Areas: Install spring washers in high-motion areas like doors, gates, or machinery to maintain secure fastenings over time.

- DIY Repairs: Keep a variety of washers in your toolbox to address diverse needs, from basic repairs to specialised tasks.

The Impact of Washers on Durability

Washers may seem like minor components, but their impact on the overall durability of an assembly is important.

They minimise wear and tear, protect materials, and ensure the reliability of the connection.

For homeowners and DIY enthusiasts, understanding and properly using washers can prevent costly repairs and extend the life of their projects.

By following our best practices for washer selection and installation, you can ensure safe and effective results. Whether it’s a small repair or a larger project, washers are indispensable tools in achieving a robust and lasting solution.

Where to Purchase Washers From?

So after reading this guide you know a little more about washers!

The next time you’re working on an installation or repair, don’t underestimate the humble washer. With the right type, placement, and technique, you can improve the quality of your work and secure your assemblies with confidence.

For a wide range of washers, along with other fixings and fasteners choose Fix and Fast.

Why?

As part of FR Scott Ltd they have 80 years experience in supplying fixings and fasteners. With a knowledgeable customer service team that specialise in fixings, that are on hand ove rthe phone or on email to offer support and guidance.

All fixings from Fix and Fast are available in bulk or in non box quantities. No forcing you to buy 200 when you only need 4!

Fix and Fast also offer next day delivery across the UK and are rated excellent on Trustpilot.